High-temperature corrosion resistance

Sanicro® 28 has excellent high-temperature corrosion properties and its high chromium content makes it resistant to gas corrosion. It is, therefore, a good material for reducing atmospheres and low NOx firing, e.g. for use in water walls, evaporators, and superheaters in various steam boiler applications such as black liquor recovery, municipal refuse, waste heat, and biomass boilers.

Our composite tubes offer the following advantages:

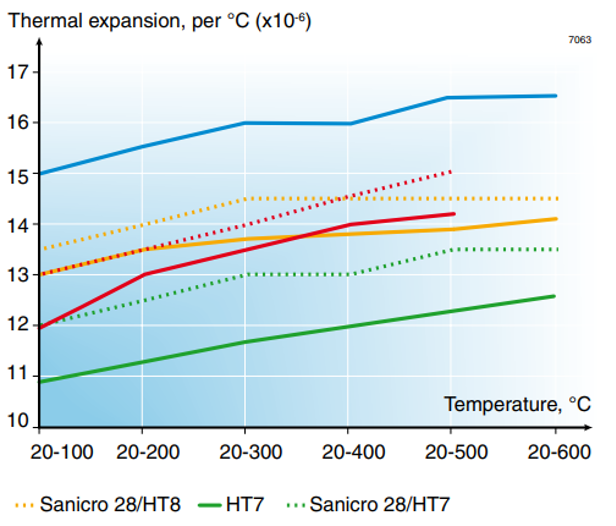

- Lower thermal expansion – reduces system stresses

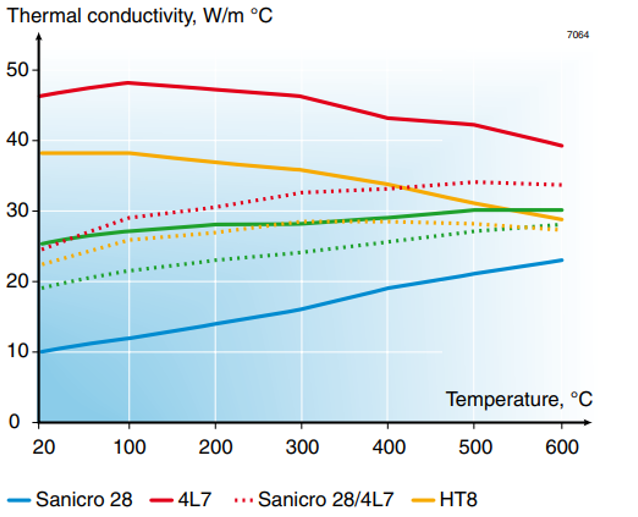

- Higher thermal conductivity – lowers the operating metal temperature, i.e. reduces corrosion

- Elimination of the risk of SCC, pitting, and crevice corrosion at the water/steam side – provide safer systems

- Joint welding of composite tubes with carbon-to-carbon or low alloy-to-low alloy welds means: – proven reliability for long-term service – good structural stability – wider tolerances for achieving precise welds – elimination of high-alloyed joints

- Easier bending – the inner carbon steel or low alloy layer supports the outer stainless layer during bending.

Developed to meet more severe conditions

Composite tubes with steel grade Sanicro® 28 as the outer component have been developed to meet more severe conditions in different types of boiler. Sanicro® 28 is an austenitic stainless alloy, initially designed for use in highly corrosive phosphoric acid applications. It has good corrosion resistance in strong acids and good resistance to stress corrosion cracking, intergranular corrosion, pitting, and crevice corrosion. Composite tubes consist of an external layer of highly alloyed stainless steel or nickel-based material, metallurgically bonded to an internal load carrier of normal carbon or low-alloyed boiler tube material. All tubes are subjected to a 100% non-destructive (ultrasonic and eddy current) examination to check for inner and outer defects, to verify the metallurgical bond, and to ensure that the thickness of the layers is within stipulated tolerances.

More than 2 million meters of composite tubes have been supplied for more than 300 boilers worldwide, confirming composite tubes as an established industry product.

More than 2 million meters of composite tubes have been supplied for more than 300 boilers worldwide, confirming composite tubes as an established industry product.

We have produced composite tubes since the early 1970s and supply the largest volumes for furnace walls in recovery boilers in the pulp and paper industry.

Grades

Outer component Sanicro® 28, UNS N08028, W.-Nr. 1.4563, EN 1.0216-5, EN 1.4563, SS 2584. Sanicro® 28 is used as composite tube cladding. The pressure vessel design calculation is based on the load-carrying component, which is a normal boiler tube material (see below). The cladding is often considered as only corrosion protection, whereas, in fact, it will add significant strength to the tube.

Typical inner components

Normal boiler tube materials such as: Alleima 4L7 (ASME SA210 A1, EN 1.0425, P265GH, W.-Nr. 1.0405, ST 45.8.III, SS 1435). Alleima HT8 (ASME SA213 T22, EN 1.7380, W.-Nr. 1.7380, 10CrMo910, SS 2218). Alleima HT7 (ASME SA213 T91, EN 1.4903, W.-Nr. 1.4903, X10CrMoVNb 9-1).

Chemical composition, Sanicro® 28 (nominal), %

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| ≤0.020 | ≤0.6 | ≤2.0 | ≤0.025 | ≤0.015 | 27 | 31 | 3.5 | 1.0 |

Chemical composition, load-carrying (normally inner) components (nominal), %

| Alleima | C | Si | Mn | P | S | Cr | Ni | Mo | Other |

| 4L7 | 0.21 | 0.3 | 0.7 | ≤0.030 | ≤0.015 | - | - | - | - |

| HT8 | 0.10 | 0.3 | 0.5 | ≤0.020 | ≤0.020 | 2.3 | - | 1.0 | - |

| HT7 | 0.10 | 0.4 | 0.5 | ≤0.020 | ≤0.010 | 8.5 | ≤0.40 | 1.0 | V, Nb, N |

Specifications

Alleima specifications 7-1-0009, 7-1-1169, 7-1-1288 PED 97/23/EC. EN 10216-2, EN 10216-5, EN 12952-2 Annex C. ASME Section I and Section II, VD-TÜV Werkstoffblatt 541 03.2001.

Mechanical properties at 20°C, Sanicro 28

| Proof strength, Rp0.2, MPa | Tensile strength, Rm, MPa | Elongation A, % | Hardness, HRB |

| ≥220 | 550-750 | ≥40 | ≤90 |

Physical properties, Sanicro 28

| Density | g/cm3 | lb/in3 |

| 8.0 | 0.29 |

Thermal expansion/conductivity

The composite tube values below have been calculated for a 63.5mm x 6.53mm minimum wall overall dimension, with a Sanicro 28 outer component = 1.65mm average wall and a carbon steel inner component = 4.88mm minimum wall.

Welding

Butt welding

Figure 1. Edge preparation.Butt welding of composite tubes should be carried out in such a way that dilution is kept under control. The melting point of the bonding zone is lower than the melting point of the stainless steel. If the bonding zone is exposed to heat input, local melting may occur. In order to obtain the optimum corrosion resistance and mechanical properties of the welded joints, the following edge preparation, figure 1, and welding sequence, figure 2, are recommended. Recommendations of welding methods, filler metal, and welding parameters are listed in table 1.

Figure 1. Edge preparation.Butt welding of composite tubes should be carried out in such a way that dilution is kept under control. The melting point of the bonding zone is lower than the melting point of the stainless steel. If the bonding zone is exposed to heat input, local melting may occur. In order to obtain the optimum corrosion resistance and mechanical properties of the welded joints, the following edge preparation, figure 1, and welding sequence, figure 2, are recommended. Recommendations of welding methods, filler metal, and welding parameters are listed in table 1.

Panel welding

Figure 2. Welding sequence.

Figure 2. Welding sequence.

Shop welding of panels should be carried out with a machine specially designed for the purpose. The weld should not penetrate the stainless steel layer of the composite tube, as this may result in hot cracking or the formation of brittle weld structures. Furthermore, excessive dilution of the fully austenitic stainless steel filler metal during fin welding (carbon steel fin) may also lead to hot cracking or a brittle weld structure.

Table 1. Welding methods, filler metal, and welding parameters

| Pass (refer to figure 2) | Welding method | Filler metal | Correspond to | Max. heat input, kJ/mm (kJ/in.) | Max. interpass °C (°F) |

|

Root run (A) |

TIG/MIG (GTAW/GMAW)/(141/132) |

Depending on load carrier used | Depending on load carrier used | Depending on load carrier used | |

|

Filler run (B) |

TIG/MIG (GTAW/GMAW)/(141/132) |

Depending on load carrier used | Depending on load carrier used | Depending on load carrier used | |

|

Top run (C) 3) |

TIG/MIG (GTAW/GMAW)/(141/132) |

Alleima 27.31.4.LCu |

AWS A5.9 ER 383 |

1,0 (25,0) |

150 (300) |

1) Higher heat input may be applied for the root and filler runs if the stainless peel off is increased.

2) Contact Alleima for advice.

3) MMA is recommended for manual welding to ensure low penetration and to maintain mechanical strength.

4) For more corrosive conditions use Alleima Sanicro 60.

Tangential panels

Figure 3. Welded tangential panel.GMAW (135/MIG) welding with Alleima 27.31.4.LCu or Sanicro® 60 welding wire is recommended for this kind of construction. Welding is performed in a single pass, from the inside of the panel, in the natural joint formed between the tubes, see figure 3.

Figure 3. Welded tangential panel.GMAW (135/MIG) welding with Alleima 27.31.4.LCu or Sanicro® 60 welding wire is recommended for this kind of construction. Welding is performed in a single pass, from the inside of the panel, in the natural joint formed between the tubes, see figure 3.

Finned panels

Figure 4. Welded finned panelGMAW (135/MIG) or SAW (12) welding are suitable methods for fabricating finned panels. The choice of filler metals depends on the fin material to be used. A basic flux should be used in SAW welding. In general, dilution should be minimized in order to avoid hot cracking or brittle weld metal structures. The impurity level in carbon steel fin materials should be considered in order to minimize the susceptibility for hot cracking.

Figure 4. Welded finned panelGMAW (135/MIG) or SAW (12) welding are suitable methods for fabricating finned panels. The choice of filler metals depends on the fin material to be used. A basic flux should be used in SAW welding. In general, dilution should be minimized in order to avoid hot cracking or brittle weld metal structures. The impurity level in carbon steel fin materials should be considered in order to minimize the susceptibility for hot cracking.

Figure 5. Edge preparation of fins.Thick fins should be beveled in order to minimize the amount of fin material in the weld, see figure 5. Bending In principle, composite tubes can be bent by the same methods as those used for single component tubes.

Figure 5. Edge preparation of fins.Thick fins should be beveled in order to minimize the amount of fin material in the weld, see figure 5. Bending In principle, composite tubes can be bent by the same methods as those used for single component tubes.

Deliveries

|

Load-carrying component |

Application | Delivery year | Quantity, m |

| 4L7 |

Copper, nickel, and lead smelting |

1993-2005 |

> 20 000 |

|

|

Municipal waste incineration |

1992-2005 |

> 10 000 |

|

|

Biomass firing |

|

|

|

|

Black liquor recovery |

|

|

|

|

Pulverized coal firing |

|

|

|

|

Coal gasification |

|

|

Figure 6. Bonding zone in a composite tube, Sanicro 28/HT7. (Sanicro 28 on ASTM A213/T91). The Sanicro 28 component is shown at the top of the figure.

Figure 6. Bonding zone in a composite tube, Sanicro 28/HT7. (Sanicro 28 on ASTM A213/T91). The Sanicro 28 component is shown at the top of the figure.

Quality Assurance

Alleima has a quality management system approved by internationally recognized organizations. We hold for example an ASME Quality System Certificate as a Materials Organisation, approval to ISO 9001 and QS 9000, as well as approvals from LRQA, JIS, and other organizations as a materials manufacturer.

Environment

Environmental awareness is an integral part of our business and is at the forefront of all activities within our operation. We hold approval to ISO 14001. Further information

Alleima and Sanicro are trademarks owned by Alleima AB