Alleima® 1RK91 is a precipitation hardening stainless steel specifically designed for applications requiring high strength combined with good ductility in the final product and high formability in the as-delivered condition. The strength is increased after ageing of the final product.

The characteristics in general can be said to be a combination of properties of ordinary austenitic stainless and low alloyed ferritic steels. For example, elastic modulus, mechanical properties and thermal expansion are comparable to ferritic steels (such as low alloyed carbon steels or chromium steels) while corrosion resistance is more comparable to austenitic stainless steels.

- Excellent mechanical properties; very high tensile strength and hardness levels can be achieved

- Corrosion resistance comparable to ASTM 304L or ASTM 316L depending on condition

- Retained mechanical properties at temperatures up to at least 400°C (750°F)

- Very good relaxation properties

- Good weldability

Standards

- UNS: S46910

Product standards

- ASTM F899

- ISO 16061

Applications

In strip form, Alleima® 1RK91 can be used for hypo-tube application.

In wire form, Alleima® 1RK91 can be used - depending on the diameter- for surgical suture needles, blood lancets and dental tools (taps, reamers, screw drivers).

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| ≤0.02 | ≤0.5 | ≤0.5 | ≤0.020 | ≤0.005 | 12 | 9 | 4 | 2.0 | 0.9 | 0.4 |

Forms of supply

Wire in Alleima® 1RK91 can be supplied with surface finishes according to the table.

| Surface finish | Size range, mm (in.) |

|---|---|

| Coated | 0.30 - 10.00 (0.012 - 0.4) |

| Bright drawn | 0.10 - 1.50 (0.004 - 0.059) |

| Straightened and ground | 0.60 - 12.00 (0.024 - 0.47) |

The following forms of supply are available:

- Coils with weights up to 150 kg

- Various types of spools with wire weights up to 500 kg

- Straightened lengths up to 4 m

Sizes and tolerances

The diameter tolerance is normally D2 for drawn wire and h8 for ground bars. Tighter tolerance can be offered on request.

| Dimension | Diameter tolerance, +/- | Ovality, max | |||

|---|---|---|---|---|---|

| mm | in. | mm | in. | mm | in. |

| 0.10 - 0.125 | 0.004 - 0.005 | 0.004 | 0.00016 | ||

| >0.125 - 0.25 | >0.005 - 0.010 | 0.005 | 0.00020 | 0.003 | 0.00012 |

| >0.25 - 0.50 | >0.010 - 0.020 | 0.007 | 0.00028 | 0.004 | 0.00016 |

| >0.50 - 1.00 | >0.020 - 0.039 | 0.009 | 0.00035 | 0.005 | 0.00020 |

| >1.00 - 1.60 | >0.039 - 0.063 | 0.011 | 0.00043 | 0.006 | 0.00024 |

| >1.60 - 2.50 | >0.063 - 0.098 | 0.014 | 0.00070 | 0.008 | 0.00032 |

| >2.50 - 6.00 | >0.098 - 0.236 | ||||

| Diameter min. | Tolerances max. | Permissible variations |

|---|---|---|

| mm (in.) | (ISO SMS 2141) | |

| 0.6 (0.024) | 100.0 (3.937) | h8 |

Alleima® 1RK91 can also be supplied as strip.

Mechanical properties

The possible ranges for the mechanical properties both in the cold-rolled and aged condition are indicated below.

The strength level after ageing depends on the amount of cold deformation and therefore also on the final dimension.

| Condition | Tensile strength, Rm | Proof strength, Rp0.2a) | |||

|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | ||

| Bar | Cold worked | - | - | 1100 | 159 |

| Aged | 1000-2100 | 145-304 | 900-1800 | 130-261 | |

| Round wire | Cold worked Aged |

900-2150 1400-3100 |

131-312 203-450 |

- - |

- - |

| Strip | Annealed Cold rolled Cold rolled + aged |

max 750 950-1850 1400-2600 |

max 109 138-268 203-377 |

max 350 600-1800 1200-2500 |

max 51 87-261 174-363 |

1 MPa = 1 N/mm2

a) Rp0.2 correspond to 0.2% offset yield strength.

Examples of strength values for the heat treated (aged) condition are shown below. As the true values depend on product form and production route, the exact value for a specific product or application must be determined in each case. Please contact Sandvik for further information.

At elevated temperatures

The values represent testing on material cold worked to a tensile strength of 1650 MPa and subsequently aged at 475°C to 530°C for 4 hours.

| Temperature | Tensile strength Rm, MPa | ||||

|---|---|---|---|---|---|

| °C | 20 | 100 | 200 | 300 | 400 |

| Bar form Wire and strip form |

2000 2450 |

1900 2400 |

1770 2200 |

1630 2125 |

1510 1975 |

Physical properties

The physical properties of a steel are related to a number of factors, including alloying elements, heat treatment and manufacturing process. The data presented below can generally be used for rough calculations.

Density: 7.9 g/cm3, 0.29 lb/in3

Resistivity: cold worked: 0.97 μΩm, aged: 0.83 μΩm

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h°F |

|---|---|---|---|

| 20 | 14 | 68 | 8 |

| 100 | 16 | 200 | 9 |

| 200 | 18 | 400 | 10.5 |

| 300 | 20 | 600 | 11.5 |

| 400 | 21 | 700 | 12 |

1) For material in heat treated (aged) condition

| Temperature °C | J/kg °C | Temperature °F | Btu/ft h°F |

|---|---|---|---|

| 20 | 455 | 68 | 0.11 |

| 100 | 490 | 200 | 0.12 |

| 200 | 525 | 400 | 0.13 |

| 300 | 560 | 600 | 0.14 |

| 400 | 600 | 700 | 0.14 |

1) For material in heat treated (aged) condition

Thermal expansion

Average values in temperature ranges. The steel grade has a coefficient of thermal expansion close to that of carbon steel. This gives it definite design advantages over normal austenitic stainless steels.

| Grade | Temperature range, °C | |||

|---|---|---|---|---|

| 30-100 | 30-200 | 30-300 | 30-400 | |

| Cold worked | 11.5 | 11.5 | 11.5 | 11.5 |

| Aged | 11.5 | 12 | 12 | 12.5 |

| For comparison: | ||||

| Carbon steel (0.2%C) | 12.5 | 13 | 13.5 | 14 |

| ASTM 304L | 16.5 | 17.5 | 18 | 18 |

1) (x10-6/°C)

| Grade | Temperature range, °F | |||

|---|---|---|---|---|

| 86-200 | 86-400 | 86-600 | 86-700 | |

| Cold worked | 6.5 | 6.5 | 6.5 | 6.5 |

| Aged | 6.5 | 6.5 | 7 | 7 |

| For comparison: | ||||

| Carbon steel (0.2%C) | 7 | 7 | 7.5 | 7.5 |

| ASTM 304L | 9.5 | 9.5 | 10 | 10 |

1) (x10-6/°F)

Modulus of elasticity

The E-modulus depends on dimension and amount of cold deformation in the material. For bar form there is no data available, but for wire and strip E-modulus between 185 - 200 X 103 MPa have been achieved.

Corrosion resistance

Alleima® 1RK91 has a corrosion resistance comparable to ASTM 304L or ASTM 316L depending on condition and environment.

Pitting and crevice corrosion

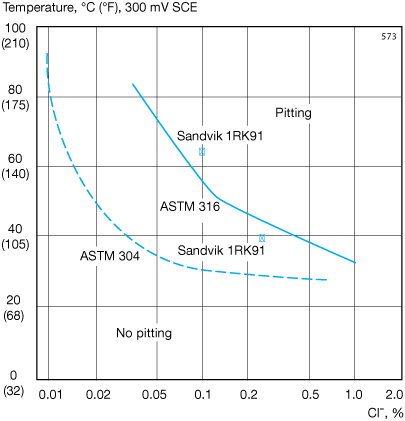

The Critical Pitting Temperature (CPT) has been determined using electrochemical CPT testing at 300 mV in NaCl solutions of different concentrations at pH = 6.0, ground test samples (600 µm). All results are average values from six measurements.

Figure 1. Critical pitting temperatures (CPT) for Alleima® 1RK91, ASTM 304 and ASTM 316 at varying concentrations of sodium chloride. Potentiostatic determinations at +300 mV SCE, pH = 6.0.

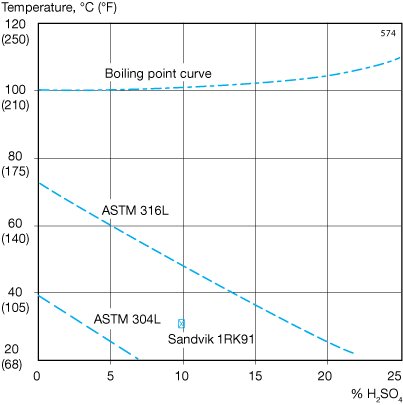

General corrosion

Figure 2. Isocorrosion diagram for Alleima® 1RK91, ASTM 304L and ASTM 316L in stagnant sulphuric acid. The curves for ASTM 304L and ASTM 316L and the dot for Alleima®1RK91, represent a corrosion rate of 0.1 mm/year

Heat treatment

Alleima® 1RK91 was originally developed for applications requiring ultra-high strength in combination with good fracture toughness.

In the annealed condition,Alleima® 1RK91 has an austenitic microstructure. To be able to precipitation harden the material and take advantage of the remarkably high ageing (tempering) effect, the matrix has first to be hardened and, thereby, partly transformed to martensite. Strength increases dramatically for wire following heat treatment at a temperature of approximately 475oC (885oF), at which point precipitation occurs in the martensitic matrix. This heat treatment is called ageing or tempering and is best carried out on the final product. This takes advantage of the good formability of the material in the as delivered condition.

For wire in Alleima® 1RK91, optimum ageing is made at 475oC (885oF) for 4 hours. Examples of the ageing effect on tensile strength are given below.

| Tensile strength | |||

|---|---|---|---|

| MPa | MPa | ksi | ksi |

| Cold worked | Aged | Cold worked | Aged |

| 950 | 1300 | 135 | 189 |

| 1000 | 1600 | 145 | 232 |

| 1200 | 2000 | 174 | 290 |

| 1500 | 2300 | 218 | 334 |

| 1800 | 2600 | 261 | 377 |

Disclaimer: Alleima is not providing any products or services that are intended or may be construed to be recommending or otherwise advising on, in any manner, the design, suitability, appropriateness or effectiveness, from a medical/biological/safety perspective, of any medical material, instrument and/or medical device.