Sanicro® 31HT is an austenitic nickel-iron-chromium alloy characterized by:

- High creep strength

- Very good resistance to oxidation

- Good resistance to combustion gases

- Very good resistance to carburization

- Good resistance to nitrogen absorption

- Good structural stability at high temperatures

- Good weldability

Sanicro® 31HT can be used at temperatures up to about 1100°C (2010°F). In order to have the best ductility, it should be used above 700°C (1290°F).

This material can also be supplied in a modified version with the chemical composition and heat treatment adapted for the highest possible creep ductility.

This version is required according to VdTÜV 434 for use in the temperature range between about 550 and 700°C (1020-1290°F).

Contact us for further information.

Sanicro® 31HT is not generally used under wet corrosive conditions. For this type of environment, we recommend Sanicro® 30, which is specially adapted for wet corrosive conditions up to about 550°C (1020°F).

Standards

- UNS: N08810/N08811

- EN Number: 1.4959/1.4876

- EN Name: X8NiCrAlTi32-21

- W.Nr.: 1.4959*/1.4876**

- DIN: X 10 NiCrAlTi 32 20*/X 5 NiCrAlTi 31 20**/X 10 NiCrAlTi 32 20 H***

Product standards

Seamless tube and pipe

- ASTM A213, A312, B163, B407

- EN 10216-5, 10297-2

- *) DIN 17459

- **) SEW 470

Approvals

Approved for use in ASME Boiler and Pressure Vessel Code, Section I and VIII, Division 1, Case 1987-2 and Section I, case 1325-16.

***) VdTÜV-Werkstoffblatt 434 (Temp. >700°C)

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.07 | 0.6 | 0.6 | ≤0.015 | ≤0.010 | 20.5 | 30.5 | 0.5 | 0.5 |

By agreement the material can be delivered with a maximum cobalt content of 0.020%.

Fe=Bal.

Applications

Sanicro® 31HT has high strength and structural stability at high temperature and very good ductility. The most common applications for this grade are :

- Pigtails and headers in plants for the production of synthetic gas for ammonia, methanol and town gas

- Furnace tubes in the production of vinyl chloride, ethylene and radiant tubes

- Heat exchanger tubing for fluidized bed combustion

- Muffle tubes in continuous wire annealing furnaces

- Thermocouple protection tubes

Corrosion resistance

Air

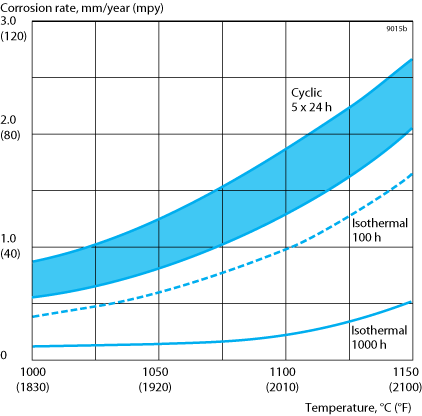

Sanicro® 31HT is highly resistant to oxidation, both at constant and at cyclically varying temperatures. See Fig. 2. The service temperature in air should not exceed about 1100°C (2010°F).

Isothermal oxidation at 1100°C (2010°F) for 100h results in a corrosion rate of about 0.8 mm/year (32 mpy) and exposure at the same temperature for 1000 h causes about 0.2 mm/year (8 mpy). This corresponds to an oxide layer of about 0.1 mm (0.004 in.) thickness after the first year, in accordance with the law of parabolic growth.

Cyclic oxidation at 1100°C (2010°F) for 5 x 24 h, with cooling to room temperature every 24 hours gives a corrosion rate of less than 1.9 mm/year (75 mpy). The corresponding corrosion rate at 1150°C (2100°F) is less than 2.3 mm/year (92 mpy). The oxidation process is accelerated by temperature fluctuations and also by plastic deformation, e.g. creep.

Carburizing atmosphere

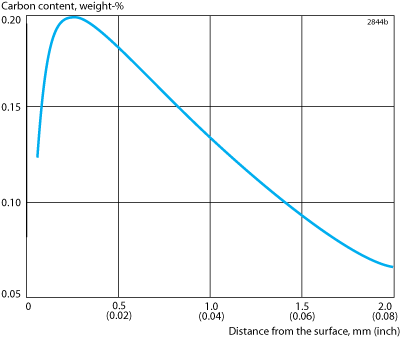

Carburization can occur when a material comes into contact with hot gases with high carbon activity, e.g. hydrocarbons. The degree of carburization depends on the composition of the material and on the carbon and oxygen contents. Consequently, a protective oxide is easily formed on the surface of the material, and this grade has, therefore, good resistance to carburization in carbon monoxide and carbon dioxide. See Fig. 3.

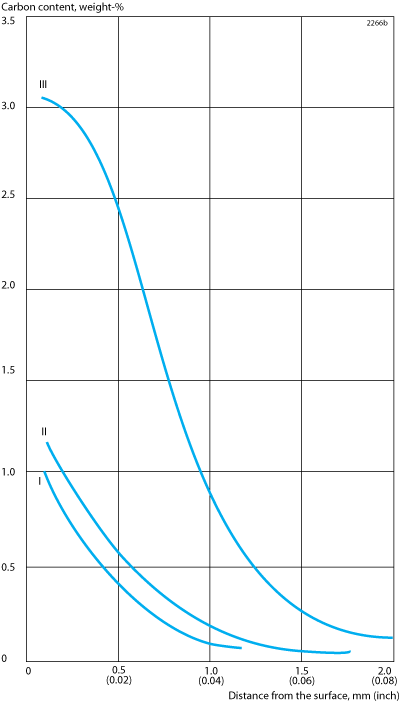

The material carburizes in gases with low oxygen content, but the depth of penetration is limited by the high content of chromium and nickel. Fig. 4 shows carburization in a mixture of 10% methane and 90 % argon. The figure also indicates to the influence of surface finish on carburization resistance.

In alternately oxidizing and carburizing atmospheres, alloys of high nickel content are sometimes attacked by what is known as "green rot". Sanicro® 31HT has good resistance to this type of attack.

Figure 3. Carburization of a cylindrical test piece after exposure in charcoal, with barium carbonate added, for 500 h 1000°C (1830°F).

Figure 3. Carburization of a cylindrical test piece after exposure in charcoal, with barium carbonate added, for 500 h 1000°C (1830°F).

Other gaseous atmospheres

In addition to its very good resistance to oxidation and carburization, Sanicro® 31HT also has good resistance to combustion gases and other aggressive gaseous mixtures. Its maximum service temperature in a sulphurous atmosphere, however, is lower than in air, and is mainly determined by the oxygen and sulphur contents of the gas.

This grade can also be used in synthesis gas (ammonia synthesis) at high process temperatures since the material has a resistance to nitrogen absorption, which is far superior to that of the ordinary 18/8 grades, and in gases containing chlorides (e.g. EDC) up to 650 °C (1200 °F) if the Ti+Al content is restricted to 0.7 % (see "Structural stability").

Salt melts

Sanicro® 31HT has good resistance to cyanide melts and neutral salt melts at high temperatures.

Figure 4. Carburization of samples with various surface finishes in 10% CH<sub>4</sub> + 90% Ar for 1000h at 900°C (1650°F).<br />I Electrolytically polished surface<br />II Machined surface<br />III Surface pre-oxidized in air for 5 hours at 1000°C (1830°F).

Figure 4. Carburization of samples with various surface finishes in 10% CH<sub>4</sub> + 90% Ar for 1000h at 900°C (1650°F).<br />I Electrolytically polished surface<br />II Machined surface<br />III Surface pre-oxidized in air for 5 hours at 1000°C (1830°F).

Wet corrosion

Sanicro® 31 HT has roughly the same resistance as Alloy 800 to general corrosion and pitting. Thanks to the high nickel content its resistance to stress corrosion is good.

Owing to its relatively high carbon content and the heat treatment applied, Sanicro® 31HT can be prone to intergranular corrosion. This problem can be disregarded where high temperature operation is concerned, but should be observed in cases when the alloy is exposed to corrosive condensates or pickling solutions.

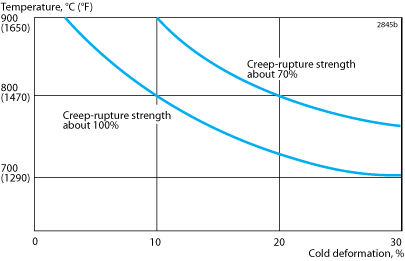

Bending

Annealing after cold bending is not normally necessary, but this should be reviewed depending on the degree of bending and the operating conditions. Figure 5 shows the connection between the degree of deformation, service temperature and creep rupture strength at 100 000 h for Sanicro® 31HT. The curves are based on data from creep tests at 700, 800 and 900°C (1290, 1470 and 1650°F respectively). For degrees of deformation and service temperatures exceeding the curve for 100% creep strength, we recommend solution annealing after cold working in order to achieve the highest possible creep strength. Further information can be supplied on request.

Hot bending is carried out at 1100-850°C (2010-1560°F) and should be followed by solution annealing.

Figure 5. Connection between degree of deformation, service temperature and creep rupture strength at 100 000 h for Sanicro 31HT.

Figure 5. Connection between degree of deformation, service temperature and creep rupture strength at 100 000 h for Sanicro 31HT.

Forms of supply

Seamless tube and pipe - finishes and dimensions

Seamless tube and pipe in Sanicro® 31HT is supplied in dimensions up to 260 mm outside diameter in the solution annealed and white-pickled condition.

Pigtail tubes, which are solution annealed after bending are supplied unpickled.

Stock sizes

Sanicro® 31HT is stocked in sizes from 3/8" to 2" outside diameter. Additional data concerning sizes and finishes is available on request from your nearest Alleima office.

Other forms of supply

Billets

Heat treatment

Tubes are delivered in the heat treated condition. If another heat treatment is needed after further processing the following is recommended:

Solution annealing

1150-1200°C (2100-2190°F), 10-30 minutes, rapid cooling in air or water.

Mechanical properties

At 20°C (68°F)

| Proof strength | Tensile Strength | Elong. | Hardness | ||

|---|---|---|---|---|---|

| Rp0.2 1) | Rp1.0 1) | Rm | A2) | A2" | HRB |

| MPa | MPa | MPa | % | % | |

| ≥172 | ≥210 | 500-700 | ≥35 | ≥30 | ≤90 |

1 MPa = 1 N/mm2

| Proof strength | Tensile Strength | Elong. | Hardness | ||

|---|---|---|---|---|---|

| Rp0.2 1) | Rp1.0 1) | Rm | A2) | A | HRB |

| ksi | ksi | ksi | % | % | |

| ≥25 | ≥29 | 73-102 | ≥35 | ≥30 | ≤90 |

1) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength, respectively.

2) Based on L0 = 5.65 √S0 where L0 is the original gauge length and S0 the original cross-sectional area.

At high temperatures

| Temperature | Proof strength | Tensile strength | |

|---|---|---|---|

| Rp0.2 | Rp1.0 | Rm | |

| °C | MPa | MPa | MPa |

| min. | min. | min. | |

| 100 | 150 | 175 | 415 |

| 200 | 130 | 155 | 385 |

| 300 | 120 | 145 | 375 |

| 400 | 110 | 135 | 370 |

| 500 | 105 | 125 | 360 |

| 600 | 95 | 115 | 345 |

| 700 | 90 | 110 | 295 |

| Temperature | Proof strength | Tensile strength | |

|---|---|---|---|

| Rp0.2 | Rp1.0 | Rm | |

| °F | ksi | ksi | ksi |

| min. | min. | min. | |

| 200 | 22.0 | 25.7 | 60.7 |

| 400 | 18.9 | 22.5 | 55.9 |

| 600 | 17.1 | 20.8 | 54.3 |

| 800 | 15.8 | 19.2 | 53.3 |

| 1000 | 14.6 | 17.6 | 51.4 |

| 1200 | 13.5 | 16.4 | 46.6 |

| 1400 | 12.8 | 15.2 | 40.9 |

Creep strength

Metric units Imperial units

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 600 | 127 | 1100 | 19.2 |

| 625 | 106 | 1150 | 15.9 |

| 650 | 88 | 1200 | 12.9 |

| 675 | 71 | 1250 | 10.2 |

| 700 | 57 | 1300 | 8.0 |

| 750 | 40 | 1400 | 5.4 |

| 800 | 27 | 1500 | 3.6 |

| 850 | 19 | 1600 | 2.4 |

| 900 | 13 | 1700 | 1.6 |

| 950 | 8.6 | 1800 | 1.0 |

| 1000 | 6.2 | 1900 | 0.7 |

| 1050 | 4.0 | 2000 | 0.4 |

| 1100 | 2.7 |

1) 100 000 h, average values

The above values generally exceed the corresponding data contained in ASME Code Case 1987 and VdTÜV-Wb 434.

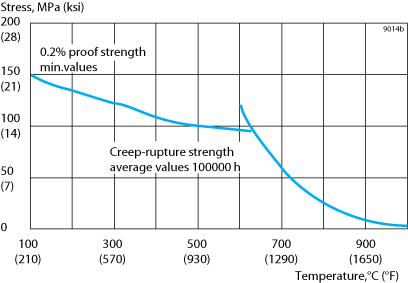

The temperature above which design calculations are based on creep rupture strength instead of 0.2% proof strength can be read off from Fig. 1.

This shows that in the case of Sanicro® 31HT, the temperature is about 650°C (1200°F).

Physical properties

Density: 7.9 g/cm3, 0.29 lb/in3

| Temperature, °C | J/kg °C | Temperature, °F | Btu/lb °F |

|---|---|---|---|

| 20 | 470 | 68 | 0.11 |

| 100 | 495 | 200 | 0.12 |

| 200 | 520 | 400 | 0.12 |

| 300 | 545 | 600 | 0.13 |

| 400 | 570 | 800 | 0.14 |

| 500 | 585 | 1000 | 0.14 |

| 600 | 605 | 1200 | 0.15 |

| 700 | 615 | 1400 | 0.15 |

| 800 | 630 | 1600 | 0.15 |

| 900 | 640 | 1800 | 0.15 |

| 1000 | 655 | 2000 | 0.16 |

| 1100 | 665 |

| Temperature, °C | W/m °C | Temperature, °F | Btu/(ft h °F) |

|---|---|---|---|

| 20 | 12 | 68 | 6.5 |

| 100 | 13 | 200 | 7.5 |

| 200 | 16 | 400 | 9 |

| 300 | 17 | 600 | 10 |

| 400 | 19 | 800 | 11.5 |

| 500 | 21 | 1000 | 12.5 |

| 600 | 22 | 1200 | 13.5 |

| 700 | 24 | 1400 | 14 |

| 800 | 25 | 1600 | 15 |

| 900 | 26 | 1800 | 16 |

| 1000 | 28 | 2000 | 16.5 |

| 1100 | 29 |

| Temperature, °C | Per °C | Temperature, °F | Per °F |

|---|---|---|---|

| 30-100 | 15 | 86-200 | 8.5 |

| 30-200 | 16 | 86-400 | 9 |

| 30-300 | 16.5 | 86-600 | 9 |

| 30-400 | 16.5 | 86-800 | 9.5 |

| 30-500 | 17 | 86-1000 | 9.5 |

| 30-600 | 17 | 86-1200 | 9.5 |

| 30-700 | 17.5 | 86-1400 | 10 |

| 30-800 | 18 | 86-1600 | 10 |

| 30-900 | 18 | 86-1800 | 10.5 |

| 30-1000 | 18.5 |

1) Mean values in temperature ranges (x10-6)

| Temperature, °C | µΩm | Temperature, °F | µΩin. |

|---|---|---|---|

| 20 | 0.99 | 68 | 38.9 |

| 100 | 1.01 | 200 | 39.9 |

| 200 | 1.03 | 400 | 40.5 |

| 300 | 1.05 | 600 | 41.4 |

| 400 | 1.08 | 800 | 43.0 |

| 500 | 1.12 | 1000 | 45.1 |

| 600 | 1.18 | 1200 | 46.9 |

| 700 | 1.21 | 1400 | 48.0 |

| 800 | 1.22 | 1600 | 48.3 |

| 900 | 1.23 | 1800 | 48.7 |

| 1000 | 1.24 |

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 200 | 190 | 400 | 27.5 |

| 400 | 175 | 800 | 25.0 |

| 600 | 160 | 1200 | 22.5 |

| 800 | 145 | 1400 | 21.5 |

| 1000 | 130 | 1800 | 19.0 |

1) (x103)

Structural stability

Thanks to its high nickel content, Sanicro® 31HT shows very little tendency to precipitate embrittling phases.

Within the 600-700°C (1110-1290°F) temperature range, an intermetallic phase, gamma prime, Ni3 (Al, Ti), is precipitated, which reduces the ductility of the alloy. To avoid this precipitation some specifications prescribe maximization of the (Ti + Al) content.

Alleima supplies a modified version of Sanicro® 31HT in which chemical composition and heat treatment have been adapted to meet this requirement and give the highest possible creep ductility.

Welding

The weldability of Sanicro® 31HT is good. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

In common with all fully austenitic stainless steels, Sanicro® 31HT has low thermal conductivity and high thermal expansion. Welding plans should therefore be carefully selected in advance, so that distortions of the welded joint are minimized. If residual stresses are a concern, solution annealing can be performed after welding.

For Sanicro® 31HT, heat-input of <1.0 kJ/mm and interpass temperature of <100°C (210°F) are recommended. A string bead welding technique should be used.

Recommended filler metals for temperature <800 °C

TIG/GTAW or MIG/GMAW welding

ISO 18274 S Ni 6082/AWS A5.14 ERNiCr-3 (e.g. Exaton Ni72HP)

MMA/SMAW welding

ISO 14172 E Ni 6182/AWS A5.11 ENiCrFe-3 (e.g. Exaton Ni71)

Recommended filler metals for temperature ≥800 °C

TIG/GTAW or MIG/GMAW welding

ISO 18274 S Ni 6617/AWS A5.14 ERNiCrCoMo-1 (e.g. Exaton Ni53)

MMA/SMAW welding

ISO 14172 E Ni 6117/AWS A5.11 ENiCrCoMo-1

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.