SAF™ 3207 HD is a hyper-duplex (austenitic-ferritic) stainless steel for service in highly corrosive conditions where high mechanical strength is also necessary. This makes the grade ideal for marine applications subjected to static or dynamic loading. The grade is characterized by:

- Excellent resistance to pitting and crevice corrosion

- Excellent resistance to stress corrosion cracking (SCC) in hydrogen sulfide (H2S) and chloride containing environments

- High resistance to general corrosion in acidic and caustic environments

- Excellent resistance to erosion-corrosion

- Excellent corrosion fatigue properties

- Exceptionally high mechanical strength

- Exceptionally high fatigue strength

- Physical properties that offer design advantages

- Good weldability

Standards

- UNS: S33207

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤0.8 | ≤1.5 | ≤0.035 | ≤0.010 | 32 | 7 | 3.5 |

Others: N=0.5

Corrosion resistance

General corrosion

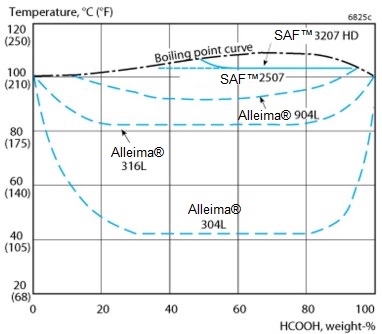

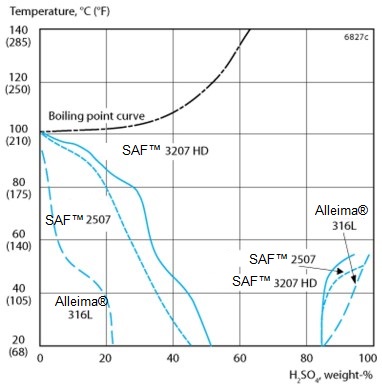

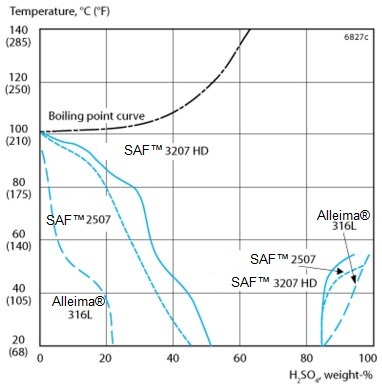

SAF™ 3207 HD is highly resistant to corrosion by organic acids (formic acid) and inorganic acids (sulphuric acid and hydrochloric acid) as shown in figures 1-3.

Figure 1. Isocorrosion diagram in formic acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in a stagnant test solution.

Figure 1. Isocorrosion diagram in formic acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in a stagnant test solution.

Figure 2. Isocorrosion diagram in sulphuric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in a stagnant test solution.

Figure 2. Isocorrosion diagram in sulphuric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in a stagnant test solution.

Figure 3. Isocorrosion diagram in hydrochloric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in a stagnant test solution.

Figure 3. Isocorrosion diagram in hydrochloric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in a stagnant test solution.

Pitting and crevice corrosion

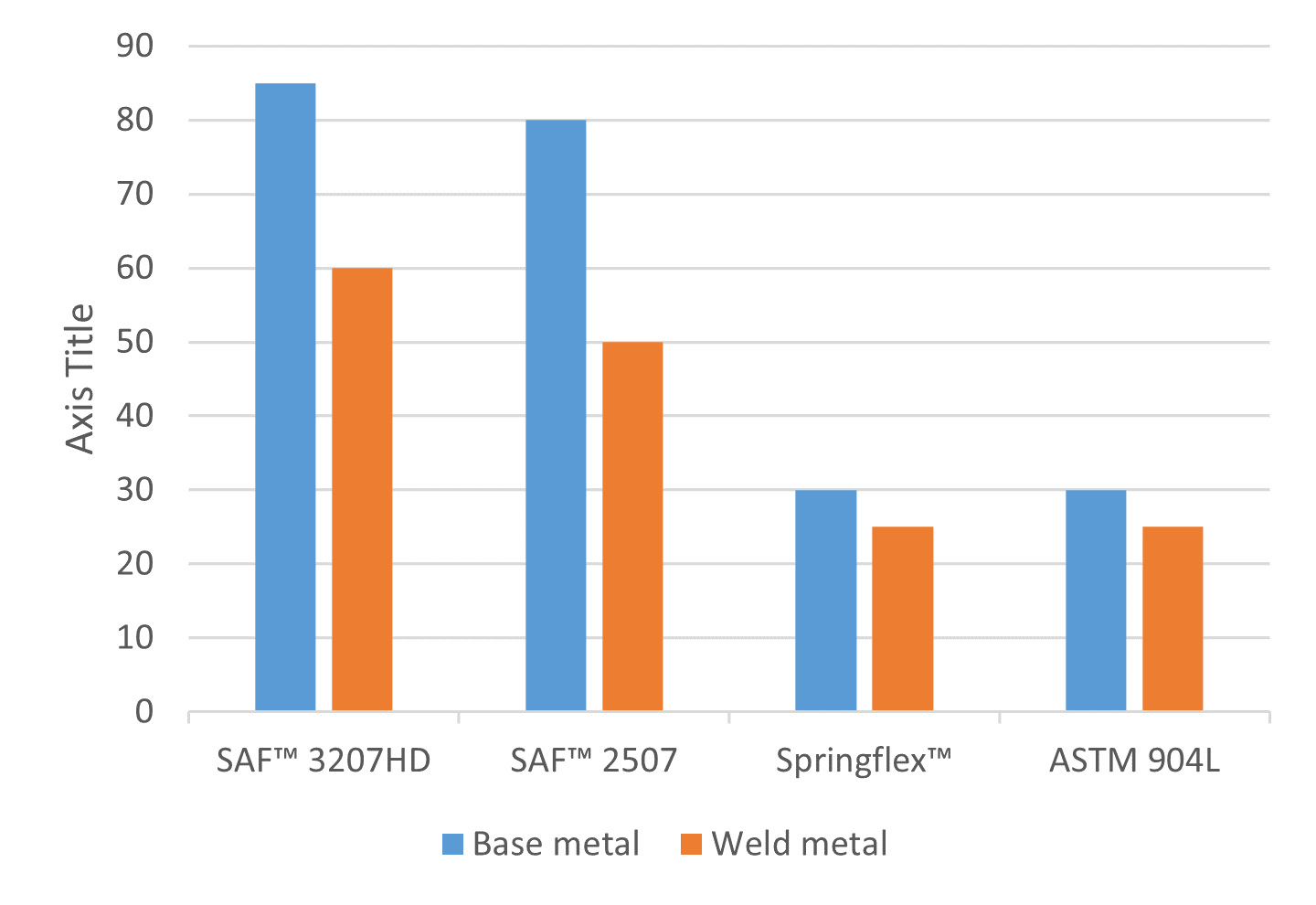

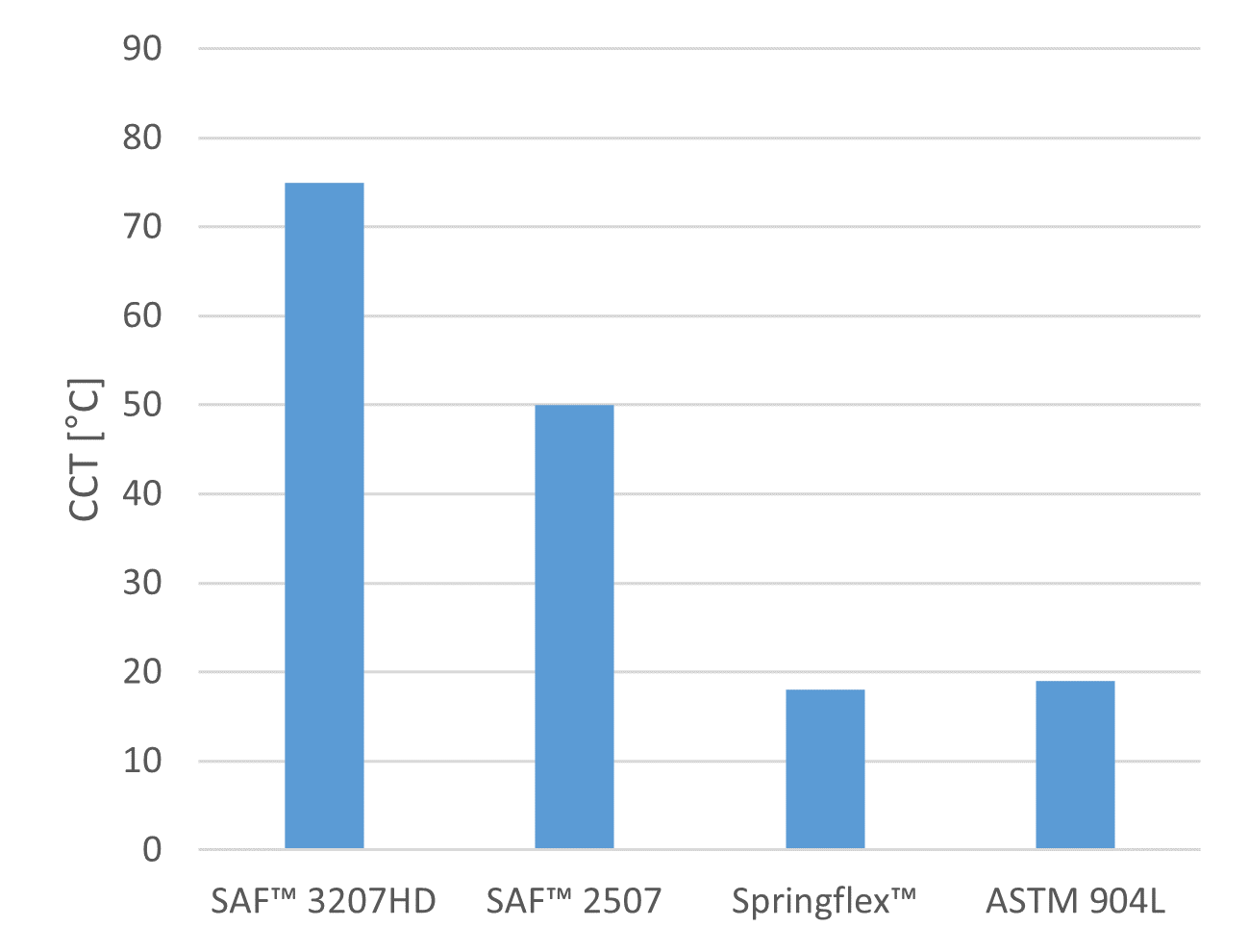

SAF™ 3207 HD is highly resistant to pitting and crevice corrosion due to high alloying levels of chromium, molybdenum and nitrogen, as shown in figures 4-5. Welding can be expected to decrease the corrosion resistance and is recommended to be performed with the support of Alleima.

Stress corrosion cracking

The standard austenitic steels of the ASTM 304L and 316L types are prone to stress corrosion cracking (SCC) in chloride bearing solutions at temperatures above 60°C (140°F). Duplex stainless steels are far less prone to this type of corrosion. Practical experience and laboratory tests have shown their good resistance to stress corrosion cracking.

Intergranular corrosion

In SAF™ 3207 HD the chemical composition is balanced in such a manner that the reformation of austenite in the heat-affected zone of a weld takes place quickly. This results in a microstructure that gives corrosion properties and toughness roughly equal to that of the parent metal. Welded joints in duplex stainless steels easily pass the intergranular corrosion test according to ASTM A262 Practice E (Strauss test).

Forms of supply

The strip steel can be supplied in coils, bundles, on plastic spools or in lengths. The edges can be either slit, deburred or smoothly rounded.

Conditions and dimensions

SAF™ 3207 HD is supplied in the solution annealed (bright annealed or annealed and pickled) or cold rolled condition.

| Thickness, mm | Width, mm | Thickness, in. | Width |

|---|---|---|---|

| mm | mm | in. | in. |

| 0.015 - 3.5 | 2 - 300 | 0.0006 - 0.14 | 0.078 - 12 |

Heat treatment

If it is necessary to restore the duplex structure after a fabrication operation, this should be done by solution annealing in a protective atmosphere at 1080-1150°C (1976-2102°F), followed by rapid cooling in air.

Mechanical properties

| Condition | Tensile strength, Rm | Proof strength, Rp0,2 | Elongation, A11,3 | ||

|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | % | |

| A | 1000 | 145 | 800 | 116 | 30 |

| C | 1450 | 210 | 1300 | 189 | 6 |

| C | 1800 | 261 | 1500 | 218 | 4 |

Rp0,2 corresponds to 0.2% offset yield strength.

1 MPa = N/mm2

A = Solution annealed

C = Cold rolled

Fatigue strength

Owing to its high strength, SAF™ 3207 HD has very good fatigue properties. The typical fatigue limit in reversed loading for 2 million cycles is about 40% of the tensile strength.

Relaxation resistance

The two-phase structure and high yield strength of SAF™ 3207 HD improves the resistance towards relaxation. Long-term bending tests have shown that austenitic grades of similar strength suffer from considerably higher relaxation. This means that a statically loaded spring made of SAF™ 3207 HD will retain its force for a longer period of time.

Bending

Despite its high strength, SAF™ 3207 HD can be readily formed and bent. In the solution annealed condition, the strip steel can be bent using a radius which is smaller than the strip thickness.

Physical properties

Density: 7.7 g/cm3 (0.28 lb/in3)

Modulus of elasticity

The modulus of elasticity of SAF™ 3207 HD is about 200 GPa at 20°C (29x103 ksi at 68°F). During loading at stresses just below the yield strength, Rp0.2, austenitic grades usually show a weakening modulus. Duplex strip steel, however, retains its modulus in a better way.

Resistivity

| Temperature, °C | μΩm | Temperature, °F | μΩin |

| 20 | 0.87 | 68 | 34.1 |

Specific heat capacity

| Temperature, °C | J/(kg °C) | Temperature, °F | Btu/(lb °F) |

|---|---|---|---|

| 20 | 480 | 68 | 0.12 |

| 100 | 510 | 200 | 0.12 |

| 200 | 540 | 400 | 0.13 |

| 300 | 570 | 600 | 0.13 |

| 400 | 590 | 800 | 0.14 |

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h°F |

|---|---|---|---|

| 20 | 13 | 68 | 7 |

| 100 | 15 | 200 | 9 |

| 200 | 16 | 400 | 9 |

| 300 | 18 | 600 | 10 |

| 400 | 20 | 800 | 12 |

Thermal expansion

| Temperature, °C | x10-6/°C | Temperature, °F | x10-6/°F |

| 30-100 | 13.5 | 86-200 | 7.5 |

| 30-200 | 13.5 | 86-400 | 7.0 |

| 30-300 | 14.0 | 86-600 | 8.0 |

| 30-400 | 14.5 | 86-800 | 8.0 |

Welding

SAF™ 3207 HD has good weldability with a good austenite reformation in the heat-affected zone. This gives the welded joint good toughness, strength and corrosion resistance.

For obtaining the best mechanical properties and corrosion resistance of the weld metal and heat-affected zone, the heat input should be within the interval 0.2-1.0 kJ/mm. The interpass temperature should be below 100°C (212°F).

For further recommendations on suitable welding parameters, please contact Alleima.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.