Solid Bar

Sanmac®2205+ is a duplex (austenitic-ferritic) stainless steel grade with excellent material cleanliness, for highly demanding applications.

Aligned to the ISO 17781 and IOGP S-563 standards (+ series).

Grade characteristics

High

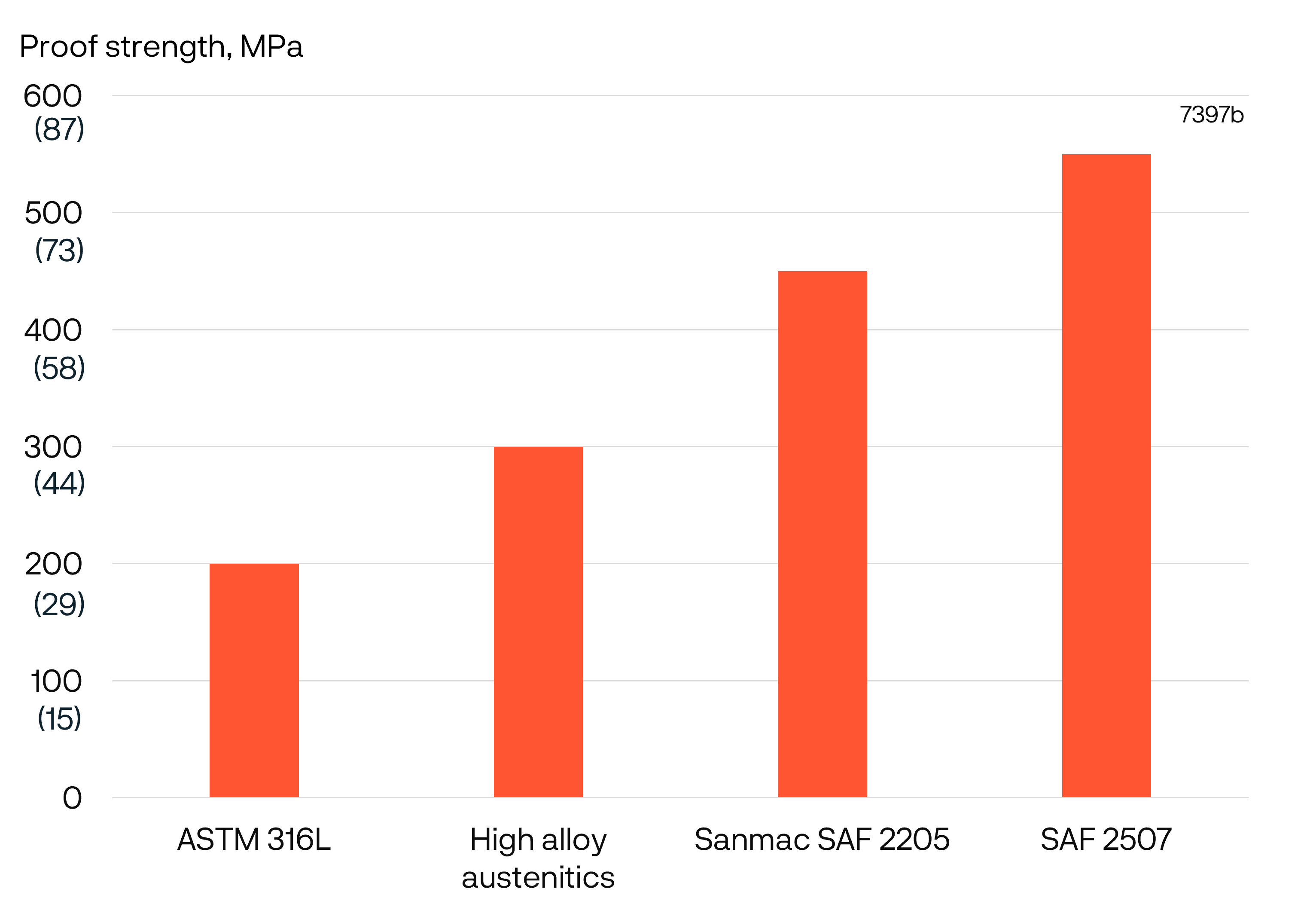

- Mechanical strength – roughly twice the proof strength of standard austenitic stainless steels

- Resistance to stress corrosion cracking (SCC) in chloride-bearing environments

- Resistance to stress corrosion cracking (SCC) in environments containing hydrogen sulfide

- Resistance to general corrosion, pitting and crevice corrosion

- Resistance to erosion corrosion and corrosion fatigue

Good

- Hot-working properties

- Weldability

Material designations

- UNS: S31803, S32205

- EN Number: 1.4462

- W.Nr.: 1.4462

Product standards

- ISO 17781:2017:QL1 (D≤215 mm / D≤8.46”)

- ISO 17781:2017:QL2 (D>215-260 mm / D>8.46”-10.23”)

- IOGP S-563:2018 (D≤260 mm / D≤10.23”)

- ASTM A-479 / ASME SA-479

- ASTM A-276 / ASME SA-276

- EN 10088-3

- EN 10088-5 (D≤160 mm / D≤6.30”)

- NORSOK M-630 2020 Rev.7, MDS D47 Rev.6 (D≤260 mm / D≤10.23”)

- NACE MR0175 / ISO 15156-3

- NACE MR0103 / ISO 17945-1

- ISO 14067:2018 (CO2e)

Chemical composition and mechanical properties only

- EN 10222-5

- EN 10272

- ASTM A-182 / ASME SA-182

Approvals

- Pressure Equipment Directive / PED (2014/68/EU)

- Pre-approval for PMA

- ISO17782:2018, NORSOK M650 Ed. 4

- DNV approved manufacturer

Climate change impact

Carbon footprint / CO2e data (kg/ton) and Life Cycle Assessment report is available for these products in the range of D 75-260 mm (D3.00”-10.23”).

Material Test Certificate

According to EN 10204/3.1

Elements nominal %

| C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤1.0 | ≤2.0 | ≤0.020 | ≤0.010 | 22.5 | 5.5 | 3.2 | 0.18 |

Applications

Due to its excellent corrosion properties, Sanmac®2205+ is a highly suitable material for service in environments containing chlorides and hydrogen sulfide.

The material is suitable for use in flowlines for the extraction of oil and gas from sour wells, in refineries and in-process solutions contaminated with chlorides.

Sanmac®2205+ is particularly suitable for chloride-bearing water or brackish water is used as a cooling medium.

The steel is also suitable for use in dilute sulphuric acid solutions and for the handling of organic acids, e.g. acetic acid and mixtures.

- The high strength of Sanmac®2205+ makes the material an attractive alternative to austenitic steels in structures subject to heavy loads.

- The good mechanical and corrosion properties make Sanmac®2205+ an economical choice in many applications by reducing the life cycle cost of the equipment.

Corrosion resistance

General corrosion

In most media, Sanmac®2205+ possesses better resistance to general corrosion than steel of type ASTM 316L and ASTM 317L. Impurities that increase corrosivity are often present in process solutions of acids.

Stress corrosion cracking

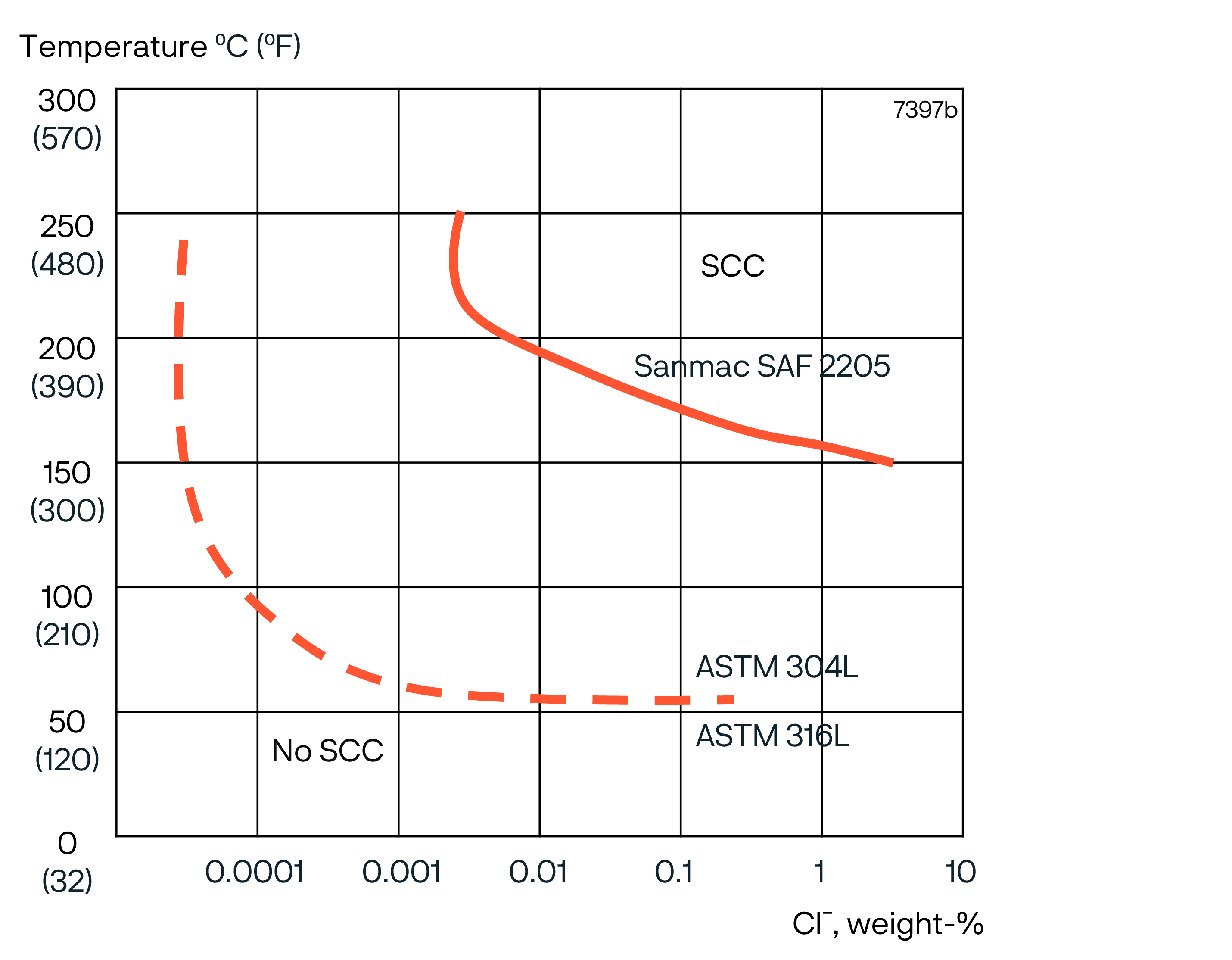

The standard austenitic steels of the ASTM 304L and ASTM 316L types are prone to stress corrosion cracking (SCC) in chloride-bearing solutions at temperatures above 60°C (140°F). Duplex stainless steels are far less prone to this type of corrosion. Laboratory tests have shown good resistance to stress corrosion cracking of Sanmac®2205+. Results from these tests are presented in figure.1.

The diagram indicates the temperature-chloride range within which Sanmac®2205+ can be used without risk of stress corrosion cracking.

ASTM 304L and ASTM 316L as reference:

Figure 1. Resistance to stress corrosion cracking, laboratory results

In accordance with NACE MR0175/ISO 15156 solution annealed and cold-worked Sanmac®2205+ is acceptable for use at any temperature up to 232°C/450°F in sour environments, if the partial pressure of hydrogen sulfide does not exceed 0.3 psi (0.02 bar) and its hardness is not greater than HRC 36.

In the solution annealed and liquid quenched condition Sanmac®2205+ is acceptable for use at any temperature up to 232°C/450°F in sour environments, if the partial pressure of hydrogen sulfide does not exceed 1.5 psi (0.1 bar).

According NACE MR0103 solution annealed and rapid quenched Sanmac®2205+, with hardness maximum 28 HRC is acceptable in sour petroleum refining.

Pitting and screvice corrosion

The pitting and crevice corrosion resistance of a steel is determined primarily by its chromium and molybdenum contents, but also by its nitrogen content as well as its slag composition and slag content. A parameter for comparing the resistance of different steels to pitting is the PRE number (Pitting Resistance Equivalent).

The PRE is defined as, in weight -%:

- PRE = % Cr + 3.3 x % Mo +16 x % N

- The PRE number for Sanmac®2205 is >35.

Intergranular corrosion

Sanmac®2205+ has a low carbon content and therefore good resistance to intergranular corrosion.

Erosion corrosion

Steels of the ASTM 316 type are attacked by erosion corrosion if exposed to flowing media containing highly abrasive solid particles, e.g. sand, or to media with very high flow velocities. Owing to its combination of high hardness and good corrosion resistance, Sanmac®2205+ displays very good resistance under such conditions.

Corrosion fatigue

Sanmac®2205+ possesses higher strength and better corrosion resistance than 316/316L austenitic stainless steels. Sanmac®2205+ therefore also possesses better fatigue strength under corrosive conditions than such steels.

Units

Metric units apply. Imperial for reference.

Forms of supply

Dimensions and finishes

Sanmac®2205+ is stocked in a number of sizes.

The standard size range for stock comprises diameters 20-260 mm

(0.78-10.23”).

Solid round bar is supplied in solution annealed, quenched and peel-turned condition.

Lengths

Bars are delivered in random lengths of 3-7 m (9.84-22.96 ft.), depending on diameter.

Tolerances

| Metric (mm) | Imperial (in.) | |||

| Diameter | Tolerance | Diameter | Tolerance | |

| 20-30 | 0/+0.13 | 0.79-1.18 | 0/+0.005 | |

| >30-50 | 0/+0.16 | >1.18-1.97 | 0/+0.006 | |

| >50-70 | 0/+0.19 | >1.97-2.76 | 0/+0.008 | |

| >70-95 | 0/+1.00 | >2.76-3.74 | 0/+0.039 | |

| >95-260 | 0/+1.50 | >3.74-10.23 | 0/+0.059 |

Straightness

| Height of arch, typical values | ||||

| Diameter, mm | mm/m | Diameter, in. | in./ft | |

| 25-75 | 1 | 0.79-2.95 | 0.06” / 5 ft. | |

| >75 | 2 | >2.95 | 0.12” / 5 ft. |

Surface condition

| Diameter | |||

| Metric (mm) | Imperial (in.) | Condition | Typical finish (Ra) |

| ≤200 | ≤7.87 | Peel turned | 2 μm |

| >200-260 | >7.87-10.32 | Peel turned | 5 μm |

Manufacturing

All products are made at the Alleima Tube AB integrated production facility in Sandviken, Sweden.

From raw materials, melting, hot working, heat treatment to finishing and testing.

Heat treatment

Solution annealing at 1020 – 1100°C (1868 – 2012°F) followed by water quenching.

Microstructure

In the solution annealed and quenched condition Sanmac®2205+ has an austenitic-ferritic microstructure, which is free from grain-boundary carbides and intermetallic phases. The ferrite content is 35 – 55%.

Mechanical properties

Tensile strength at 20°C (68°F)

The following values apply to material in the solution annealed and quenched condition bar stock size up to 260mm (10.23”).

| Proof/Yield strenght (min.) | Ultimate tensile strength (min.) | |

|---|---|---|

| Rp0.2a) | Rp1.0a) | Rm |

| 450 MPa | 500 MPa | 680-880 MPa |

| 65 Ksi | 72 Ksi | 98-127 Ksi |

Elongation: D≤260mm ≥30% D>260mm ≥25%

1 MPa = 1 N/mm 2

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength respectively.

b) Based on L0 = 5.65√S, where L0 is the original gauge length and S0 the original cross-sectional area.

Figure 2. Typical proof strength (Rp0.2) values, comparison

Impact strength

Sanmac®2205+ possesses good impact strength, both at room temperature and at low temperatures.

The Alleima bar stock program guarantees the following impact strength (Charpy-V longitudinal) at -50°C / -58°F.

ISO17781 QL1

D≤215 mm 85J average / 65J single

(D≤8.46”) (62.7 ft-lb average / 47.9 ft.lb single)

ISO17781 QL2

D>215-260 mm 65J average / 50J single

(D>7.28”-10.23”) (47.9 ft.lb average / 36.9 ft.lb single)

The impact strength at “RT” / 20°C (68°F) is min 100J average / 70J single

( 73 ft.lb average / 51 ft.lb single ).

At higher temperatures

If Sanmac®2205+ is exposed for prolonged periods to temperatures exceeding 280°C (540 °F), the microstructure changes which results in a reduction in impact strength.

This does not necessarily affect the behavior of the material at the operating temperature. Contact Alleima for advice.

For pressure vessel applications, 280°C (540°F) is required as a maximum.

Hardness

Max. 28HRC

Physical properties

Density: 7.8 g/cm3, 0.28 lb/in3

Specific heat capacity

| Temperature, °C | J/(kg °C) | Temperature, °F | Btu/(lb °F) |

|---|---|---|---|

| 20 | 480 | 68 | 0.11 |

| 100 | 500 | 200 | 0.12 |

| 200 | 530 | 400 | 0.13 |

| 300 | 550 | 600 | 0.13 |

| 400 | 590 | 800 | 0.14 |

Thermal conductivity

| Metric units | |||||

|---|---|---|---|---|---|

| Temperature,°C | 20 | 100 | 200 | 300 | 400 |

| W/(m °C) | |||||

| Sanmac® 2205+ | 14 | 16 | 17 | 19 | 20 |

| AISI 316L | 14 | 15 | 17 | 18 | 20 |

| Imperial units | |||||

|---|---|---|---|---|---|

| Temperature, °F | 68 | 200 | 400 | 600 | 800 |

| Btu/(ft h °F) | |||||

| Sanmac® 2205+ | 8 | 9 | 10 | 11 | 12 |

| AISI 316L | 8 | 9 | 10 | 10 | 12 |

Thermal expansion, mean values in temperature ranges (X10-6)

| Metric units | ||||

|---|---|---|---|---|

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| Per °C | ||||

| Sanmac® 2205+ | 13.0 | 13.5 | 14.0 | 14.5 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| AISI 316L | 16.5 | 17.0 | 17.5 | 18.0 |

| Imperial units | ||||

|---|---|---|---|---|

| Temperature, °F | 86-200 | 86-400 | 86-600 | 86-800 |

| Per °F | ||||

| Sanmac® 2205+ | 7.0 | 7.5 | 7.8 | 8.0 |

| Carbon steel | 6.8 | 7.0 | 7.5 | 7.8 |

| AISI 316L | 9.0 | 9.5 | 9.8 | 10.0 |

Figure 3. Thermal expansion

Resistivity

| Temperature, °C | μΩm | Temperature, °F | μΩin. |

|---|---|---|---|

| 20 | 0.74 | 68 | 29.1 |

| 100 | 0.85 | 200 | 33.1 |

| 200 | 0.96 | 400 | 39.8 |

| 300 | 1.00 | 600 | 43.3 |

| 400 | 1.10 | 800 | 43.3 |

Modulus of elasticity ( x103 )

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 100 | 194 | 200 | 28.2 |

| 200 | 186 | 400 | 27.0 |

| 300 | 180 | 600 | 26.2 |

Welding

The weldability of Sanmac®2205+ is good. Welding must be carried out without preheating. Subsequent heat treatment is normally not required. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

For Sanmac®2205+ heat-input of <2.5 kJ/mm and interpass temperature of <150°C (300°F) are recommended.

Recommended filler metals:

TIG/GTAW or MIG/GMAW welding

ISO 14343-A W/G 22 9 3 N L / AWS A5.9 ER2209 (e.g. Exaton 22.8.3.L)

MMA/SMAW welding

ISO 3581-A E 22 9 3 N L R / AWS A5.4 E2209-17 (e.g. Exaton 22.9.3.LR)

For welds exposed to particularly severe environments more resistant welding consumables are recommended:

TIG/GTAW or MIG/GMAW welding

ISO 14343-A W/G 25 9 4 N L / AWS A5.9 ER2594 (e.g. Exaton 25.10.4.L)

MMA/SMAW welding

ISO 3581-A E 25 9 4 N L R / AWS A5.4 E2594-16 (e.g. Exaton 25.10.4.LR)

Hot working

Sanmac®2205+ is ductile at higher temperatures. The deformation resistance increases with decreasing temperature, and hot working should therefore be carried out at a material temperature of 975-1200°C (1787-2318 °F).

If the temperature falls below 950°C (1790 oF) during hot working there is a risk for sigma phase formation, and the material must therefore be reheated.

Further hot working of Sanmac®2205+ should be followed by solution annealing and quenching in accordance with the recommendations given for heat treatment.

Machining

General

Machining is an expression used for a number of subtractive manufacturing methods.

Mainly turning, milling, drilling. But also other operations like cutting, boring, grinding, reaming and tapping.

For solid bars the initial operations primarily are cutting and external turning to prepare a blank for component manufacturing.

Stainless steels

Materials within the ISO-M material area can be challenging to machine.

The materials vary a lot within the ISO-M group, but in general presents difficult chip control, high cutting forces and tool wear.

In order to get as efficient function and tool life as possible, dedicated cutting tools and strategies to be used.

Getting started

To get it right, the first thing is to know the material to be machined.

As the material properties are input to the selection of start values.

- ISO material group

- Condition/heat treatment

- Actual hardness of the material lot

Consult your cutting tool supplier for start recommendations, since the choice of cutting tools and machine tool set the direction for which start values to use.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.